We offer a comprehensive portfolio of nickel-based alloys, stainless steels, tool steels, as well as pre-machined and fully machined forged parts.

As part of a customer-oriented management system, we handle the procurement and storage of nickel-based alloys, stainless steels, and tool steels, as well as the extended value-added chain based on customer requirements, all the way to ready-to-install parts.

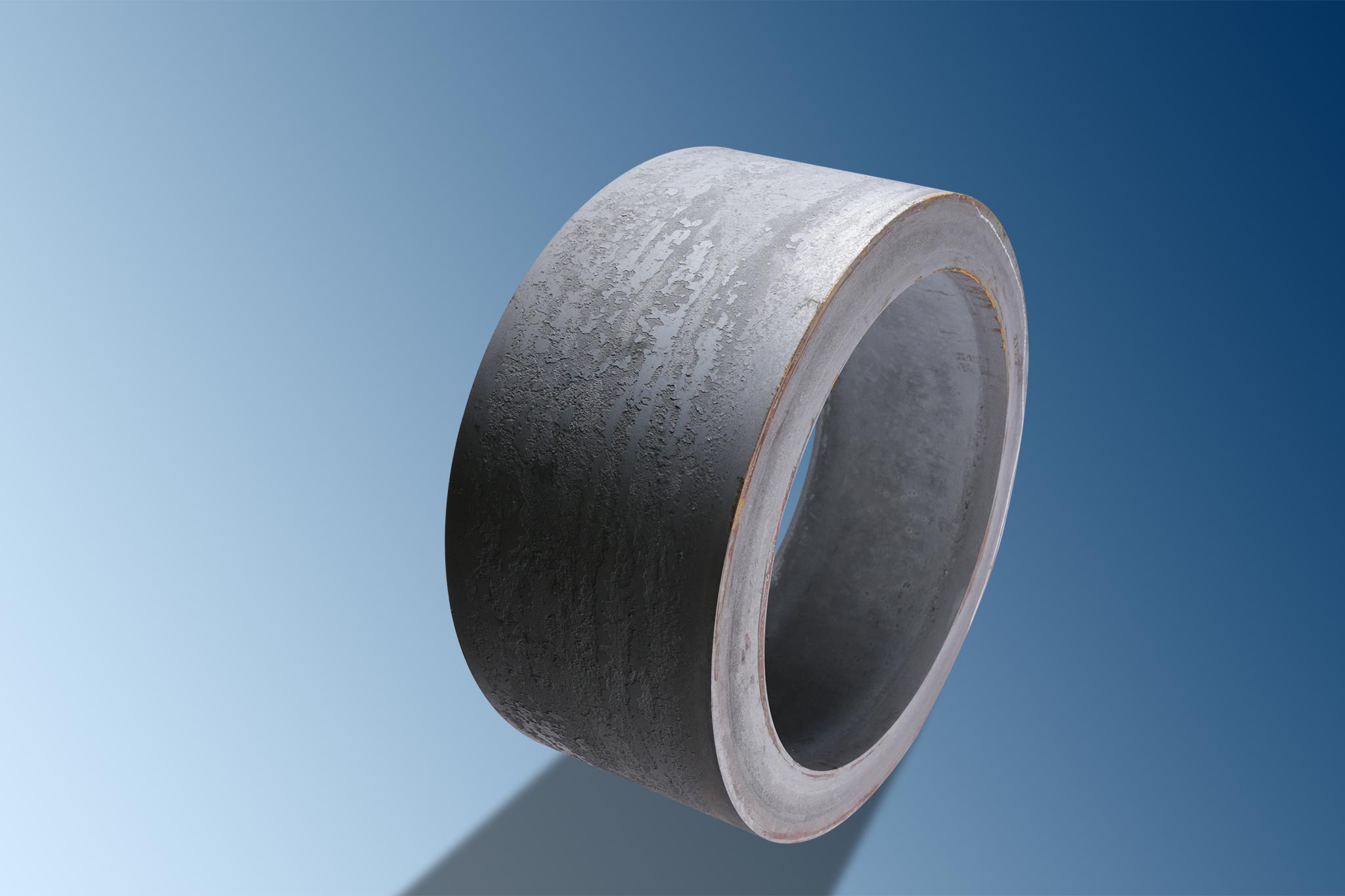

Material 2.4668 Alloy 718, aged to 44-46 HRC, turned and drilled. Application: Heavy metal extrusion presses.

More InformationMaterial 1.3467 mandrel blanks are turned, drilled, heat-treated, and machined to drawing specifications in our facility.

More InformationTurned part/ring made of stainless steel. Forged parts can be fully machined by us.

More InformationCNC turning and milling enable the highest precision and repeatability in the machining of metal parts. Ideal for complex geometries and series production, where dimensional accuracy and efficiency are crucial.

More InformationHeat treatment enhances material properties such as hardness, strength, and toughness. Through precise temperature processes, components are created that withstand extreme demands and ensure long-lasting performance.

More InformationWhether for mechanical engineering, steel construction, or vehicle technology – we provide precision-cut semi-finished products that significantly simplify your further manufacturing processes.

More Information